In automatising the bakery’s dosing systems, it is important that the mechanical dosing equipment is of a high quality but it is equally important that the system controlling the dosing process is well designed. Rarely can even the best mechanical equipment deliver an outstanding performance if the design of the control system is only half-thought out.

Dosetec’s extensive automation system experience enables us to carefully engineer all aspects of the control systems for dosing applications and to provide each customer with a detailed customised system that will integrate with either a new or an existing system.

Customised control, reliable ingredient management

The key to controlling and managing production processes is the measuring and tracing of process variables. Dosetec’s control systems are based on the intelligent logic of Siemens S7 product family. Dosing and weighing are controlled precisely and the management of batch ingredients is reliable.

Real time intelligence without interruptions

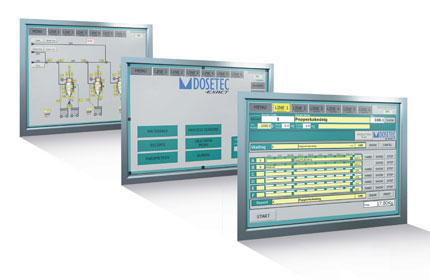

Dosetec’s control system enables the control of dosing processes without interruptions. The management and change of recipes can be done effortlessly in real time thanks to the open field bus and fast response times, which the control logic offers.

In addition, the various dosing steps and the use of ingredients can be observed in real time. Our reliable systems verify, for example, that the amount of ingredients arriving at a receiving hopper is the amount that was dosed according to the recipe and provide an alert in the event of any discrepancies or problems.

Batch and user reports are available on ingredients added by either automatic or manual dosing as well as on the outcome of the recipes.

Touch screen displays are used to control the dough temperature on each production line and to manage any possible over or under production.

Seamless connectivity

The control logic in Dosetec’s systems makes possible the easy connection to fi eld devices, such as remote I/O-stations or frequency converters. Equally important, the systems are designed to allow for expansion in case of future changes in the production processes.

Dosetec helps the customer to design and implement the connectivities in order to best utilise the fl exible, cost-effective and easy-touse dosing and to maximise the benefi ts from the dosing processes.